A “concrete small block machine” typically refers to a smaller-scale concrete block making machine suitable for lower production volumes or on-site use. These machines are often more affordable and portable than large industrial-scale operations.

Here’s a breakdown of what you need to know about concrete small block machines:

Key Features and Types:

- Production Capacity: Smaller machines have lower production capacities compared to fully automatic industrial machines. Capacities can range from a few hundred to a few thousand blocks per 8-hour shift.

- Automation Level:

- Manual: These machines require significant manual operation for tasks like material feeding, mold filling, and block removal. They are the most basic and often the most affordable.

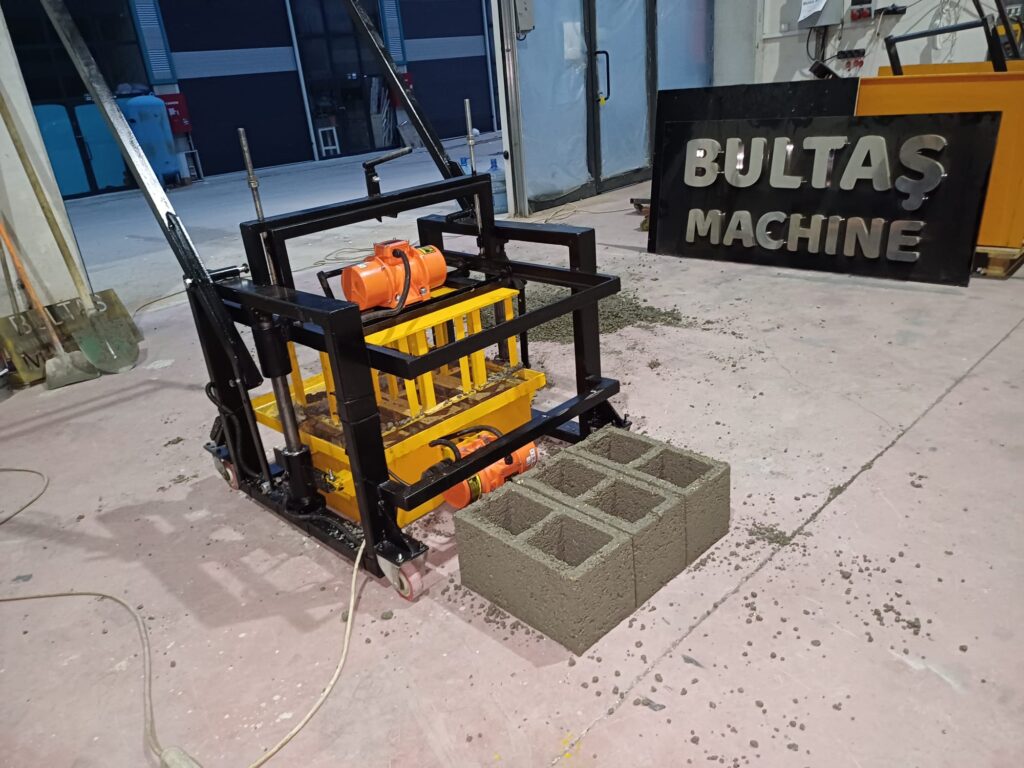

- Semi-Automatic: These machines automate some processes, such as vibration and hydraulic pressing, but still require manual assistance for other tasks.

- Mobile: These are portable machines, often with wheels, designed for on-site production. They can be manual, semi-automatic, or even automatic in some cases. They eliminate the need for transporting blocks.

- Egg-Laying (Movable): These types of mobile machines lay blocks directly on the ground and move forward, eliminating the need for pallets.

- Block Types: Most small block machines can produce various types of concrete blocks by changing the mold, including:

- Hollow blocks

- Solid blocks

- Pavers

- Interlocking blocks

- Kerbstones

- Power Source: Can be electric, diesel, or a combination. Mobile units sometimes use diesel engines for operation in areas without easy access to electricity.

- Size and Portability: Designed to be more compact and easier to transport than large stationary machines.

Advantages of Small Block Machines:

- Lower Initial Investment: Generally more affordable to purchase than fully automatic systems.

- Portability: Mobile units can be easily moved to different construction sites.

- Flexibility: Suitable for small to medium-scale projects or for producing specific block types on demand.

- Ease of Use: Manual and semi-automatic machines are often simpler to operate and maintain.

- On-Site Production: Reduces transportation costs and potential damage to blocks during transit.

Factors to Consider When Choosing a Small Block Machine:

- Production Requirements: Determine the number of blocks you need to produce daily or weekly.

- Budget: Prices vary significantly based on the level of automation, capacity, and brand.

- Types of Blocks: Ensure the machine can produce the specific block types you require.

- Available Space: Consider the footprint of the machine and the space needed for operation and storage.

- Power Availability: Choose a machine with a suitable power source for your location.

- Maintenance and Support: Inquire about spare parts availability and technical support from the manufacturer.

Small Block Machines are available from Bultaş Machinery.

Price Range:

The price of a small concrete block machine can vary significantly depending on its type, level of automation and production capacity. You can find machines ranging from a few hundred dollars for basic manual models to several thousand dollars for semi-automatic or mobile units.

All in all, concrete small block machine offers a more accessible and flexible solution for producing concrete blocks, especially for smaller projects or on-site needs. Carefully evaluate your requirements and budget to choose the right machine for your application.

Block Making Machine Manufacturer in Türkiye. best block machine here